Rice Processing

Currently our processing Capacity is 20 M/TONS P.H, the state-of-art processing plants for rice production have fully mechanized sophisticated processing procedures for different stages like cleaning, de-stoning, polishing, sorting and grading. In these hi-tech milling plants every stage conforms to international standards and stringent guidelines of process control are meticulously adhered to at every stage to ensure uniformity of grains without destroying fragrance, aroma and basic quality of grain.

Cleaning

Winnowers are relatively simple machines that consists mainly of a hopper to receive the grain, a fan and a set of sieves. Pre-cleaners: These motor-driven devices are generally used to pre-clean grains that have been harvested when moist, before it goes to the artificial dryer. Cleaner-separators: The cleaner-separators are motor-driven and consist of a reception hopper, a fan and a set of vibrating sieves that clean grain by repeated suction of the lightest impurities, followed by sifting of the grain.

Whitening & Polishing

During whitening and polishing, bran layers are removed from the brown rice. This not only enhances the appearance of the rice but also increases its shelf life, since the lipids contained in the beginning and the bran layers are highly susceptible to enzymatic and non-enzymatic oxidation. The bran removal is best achieved in several steps to ensure evenly milled rice with minimum broken grains and optimum uniformity. The whitened rice is then polished to give it a silky finish.

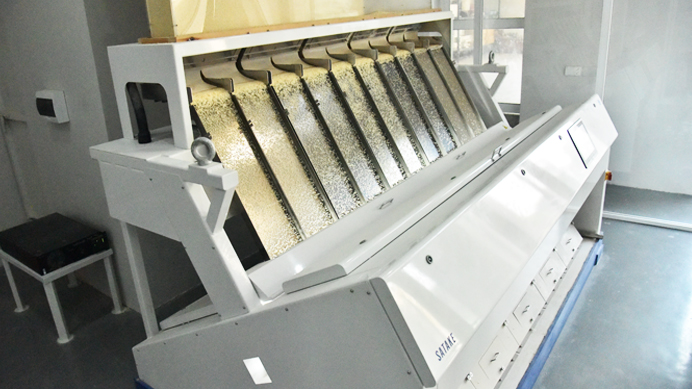

Color Sorting

Understanding our responsibility as a manufacturer of an edible product, we ensure that it is high in quality. We implement all the latest quality control measures so that each grain is of superior quality. Every lot is subject to strict laboratory test and our Sortex Machine ensures the elimination of black rice. Through innovation we have learned to use the best Sortex machines from Buhler and Satake.

Grading

Grading is the process of removing the broken grains from the head rice and sorting them into well-defined fractions of different lengths. The grading process at our mill is achieved with a Plan sifter, Classifier Separator and Indent Cylinder.

Packing & Storage

The finest quality rice is finally packed and sent out according to the market requirement and trade standards. The rice is bagged-off in our bagging station, stitched at the sewing belt, stored according to its grade and is then ready for dispatch. We at Amir Rice Mills will work with you to produce the type of rice product that will sell well for both domestic and export use and guarantee that only the finest rice reaches you